The expansion of global trade has brought a growing need for versatile, secure, and standardized logistics solutions. In this context, containers have taken on a central role, enabling the smooth movement of goods across different modes of transport: maritime, rail, and road. However, there is no single universal container model. There are multiple types of containers, each designed to meet specific cargo characteristics.

Below, we present the most commonly used types of containers in international logistics, along with a description of their technical specifications and typical uses. This guide aims to help you choose the most suitable equipment based on the shipper’s needs and the nature of the goods.

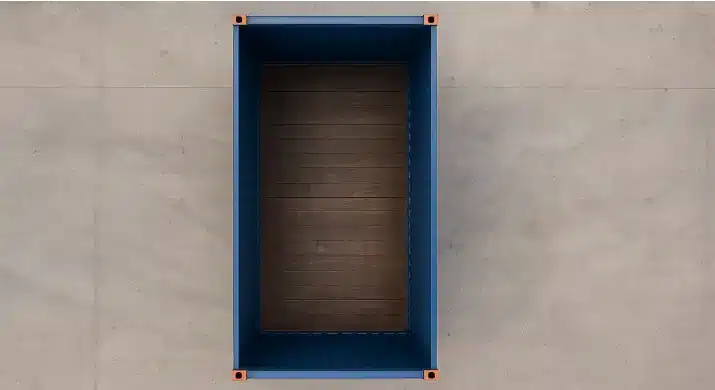

Dry Container (General Purpose)

The dry container, also known as the standard container, forms the foundation of intermodal transport systems. Fully enclosed and watertight, it is designed to protect cargo from moisture, dust, and external elements. It is widely used for palletized goods, textiles, industrial products, and packaged consumer items. Available in 20- and 40-foot sizes, its easy handling in terminals and warehouses makes it a highly versatile logistics solution.

Flat Rack

This container type has no roof or side walls, only fixed end frames. It is intended for the transport of heavy, oversized, or irregularly shaped cargo, such as machinery, pipes, or metal structures. Its design allows for side or top loading, making it ideal for use in industrial environments or construction sites.

Open Top

The open-top container features a removable roof, usually a reinforced tarpaulin, which enables vertical loading. It is commonly used for tall items that require crane handling, such as generators, transformers, or construction materials. Internal lashing rings ensure secure transportation.

Double Door Container

This model has doors on both ends, providing greater flexibility and efficiency in loading and unloading. It is especially useful for long items like pipes or beams that need to be moved in a straight line. Despite its unique design, it maintains the same weatherproofing standards as conventional containers.

High Cube

The high cube container offers additional interior height compared to the standard container, resulting in more usable volume. This type is ideal for lightweight but bulky goods like textiles, furniture, or packaging materials. The extra 30 centimeters in height make it an effective solution for maximizing vertical space.

Open Side

This container features a full side opening in addition to the standard rear doors. It allows easier handling of wide or fragile goods that need full access to the container’s interior. Open side containers are often used in operations with limited space or difficult maneuvering conditions.

Reefer Container

The refrigerated container (reefer) maintains controlled temperatures using an active cooling system that requires external power. It is essential for transporting perishable foods, pharmaceuticals, and any cargo sensitive to temperature changes. Its design ensures the integrity of the cold chain throughout the journey.

Insulated Container

Unlike reefers, insulated containers do not actively cool but instead maintain a stable temperature through passive thermal insulation. They are mainly used to transport goods that must avoid temperature fluctuations, such as medicines, cosmetics, or processed foods, especially on short or medium-haul routes.

Half-Height

As the name suggests, the half-height container is half the height of a standard one but is reinforced to support extremely dense and heavy loads. This type is frequently used in industries such as mining and construction, where materials like stone, coal, or scrap metal need to be transported securely.

ISO Tank Container

Designed for transporting bulk liquids, the ISO tank consists of a stainless-steel cylinder mounted on an ISO frame. It is commonly used in the chemical, food, and energy industries. To ensure safe transit, the tank must be filled to between 80% and 95% capacity to prevent dangerous internal sloshing.

Huckepack Container

The Huckepack container is a wheeled semi-trailer designed for intermodal road and rail transport. Its reinforced structure allows it to be loaded directly onto trains without unloading the cargo. It is ideal for long European routes, combining efficiency with sustainability.

Conclusion

The diversity of types of containers used in international trade reflects the wide range of cargo, industries, and transport routes that define today’s logistics landscape. Understanding the features, applications, and benefits of each type allows for better decision-making, more efficient operations, and reduced transit risks. Organizations such as FIATA and UNECE provide technical recommendations for operators working with various types of containers, especially in cross-border transport.

Having a logistics partner who understands these complexities is essential for achieving efficient, tailored supply chain management. In this regard, Portex offers technical expertise, strategic insight, and operational solutions aligned with international logistics standards.

Looking for a partner who understands all types of containers?

At Portex, we understand that every shipment is unique and that choosing the right container from the many available types of containers can significantly impact costs, safety, and transit times. That’s why we guide our clients with expert advice, helping them identify which container best suits the nature of their cargo and the chosen mode of transport.

Our team is well-versed in all the types of containers used in global trade, from the most standard to the highly specialized. This allows us to tailor each logistics solution to the customer’s real needs. Thanks to our experience and strategic partner network, we provide reliable, flexible service that meets the demands of every sector.

Want to know which type of truck is best for transporting your cargo?

Now that you know the key container types, it’s time to choose the right truck too. In our next article, you’ll discover the 8 most commonly used trucks in logistics, including their applications, advantages, and the most common mistakes to avoid.

Click here to read the full article about types of trucks in logistics